by REGO-FIX Team | Jul 22, 2022 | Blog

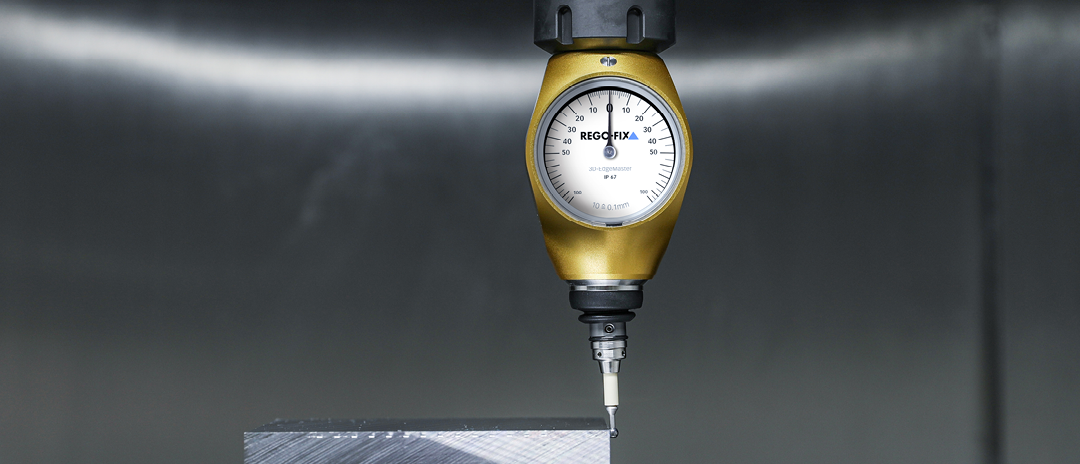

A manufacturing shop can apply the best machine tools, toolholders and cutting tools, but bad parts or even machine crashes may result if the workpiece setup is not accurate. Every element in a machining system is important for success. Precisely establishing...

by Tech Team | Jul 8, 2022 | Blog, powRgrip

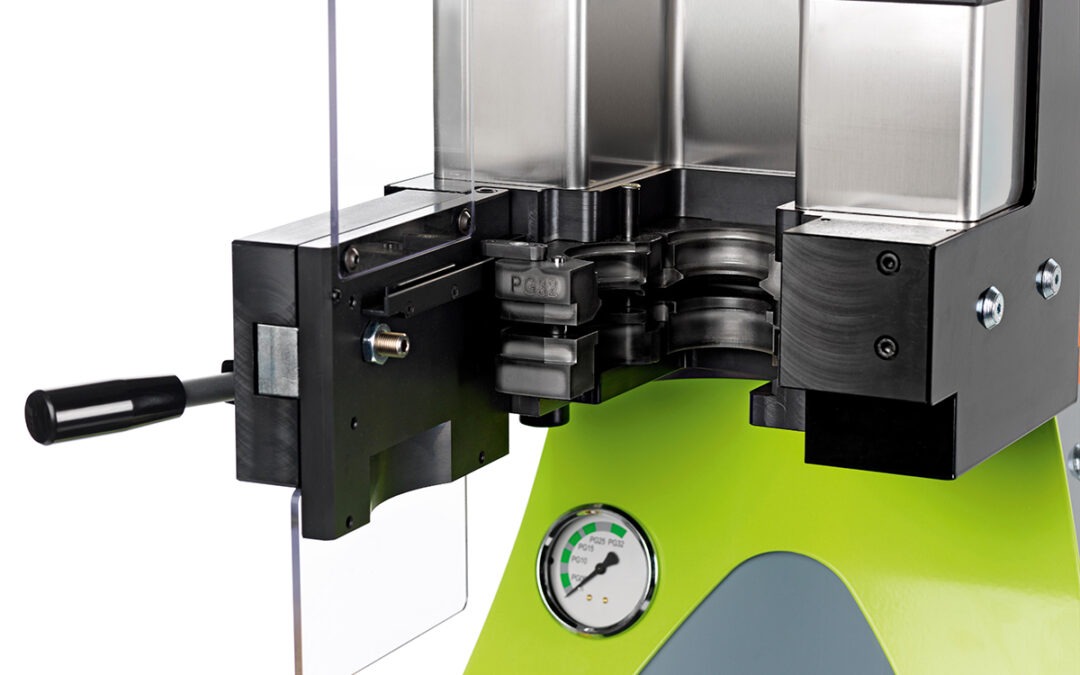

When you think about typical applications for powRgrip® high precision toolholding, the scenarios that come to mind probably center around how to cut exotic materials or meet tough specifications for demanding parts. Even though those are some of powRgrip’s...

by Tech Team | Jun 24, 2022 | Blog

In our everyday lives, we’re encouraged not to “sweat the small stuff.” In shop life, however, that casual attitude can yield some expensive consequences if you apply it to your tools and toolholding. The moments you invest in keeping these items clean can help you...

by REGO-FIX Team | Jun 10, 2022 | Blog, powRgrip

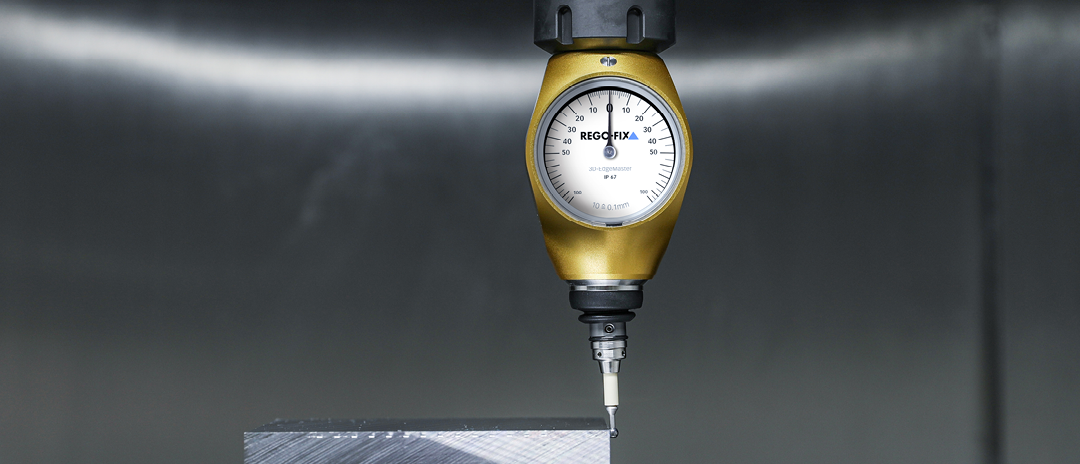

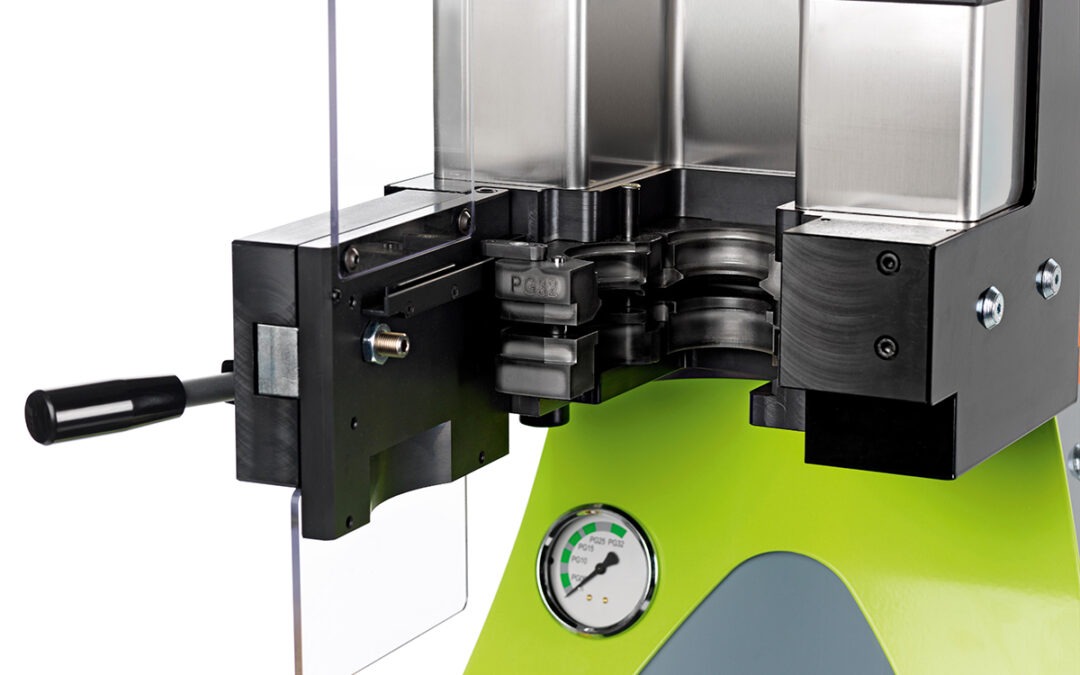

We love training customers on the powRgrip PGU 9500 toolsetting unit for two very simple reasons. First, we always want to help customers gain the fullest benefits from our technologies – and second, we truly enjoy seeing the looks on their faces when they realize how...

by REGO-FIX Team | May 27, 2022 | Blog, powRgrip

When you’ve spent as many years inventing and manufacturing high-quality toolholding as we have, you not only understand that manufacturers need precision, you’ve made it possible for them to meet that need. Beyond all our other options, we created the REGO-FIX...

by REGO-FIX Team | May 13, 2022 | Blog, powRgrip

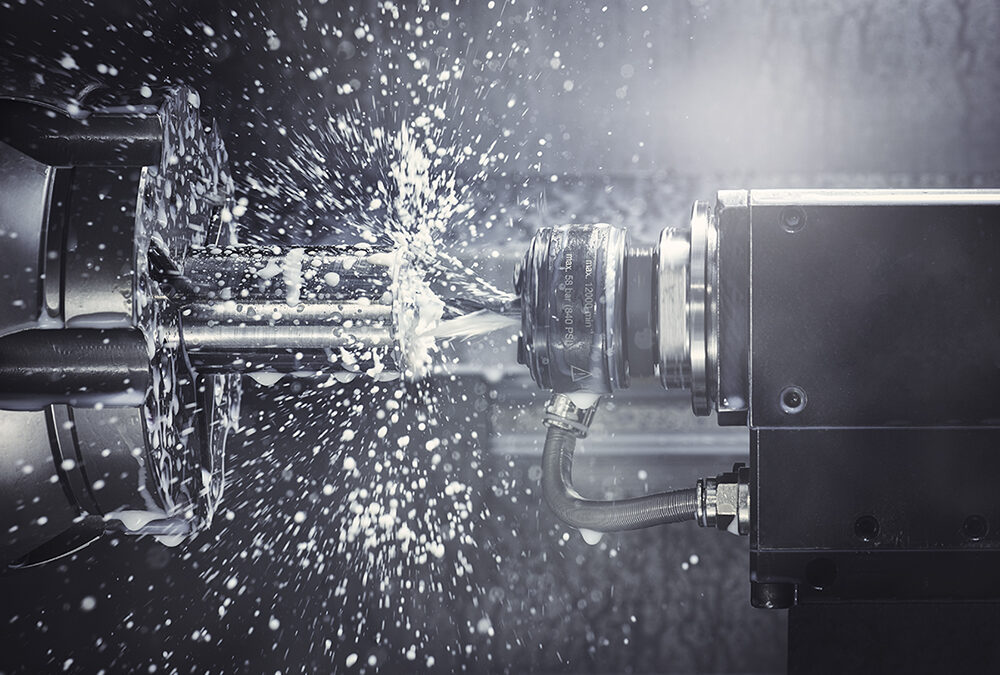

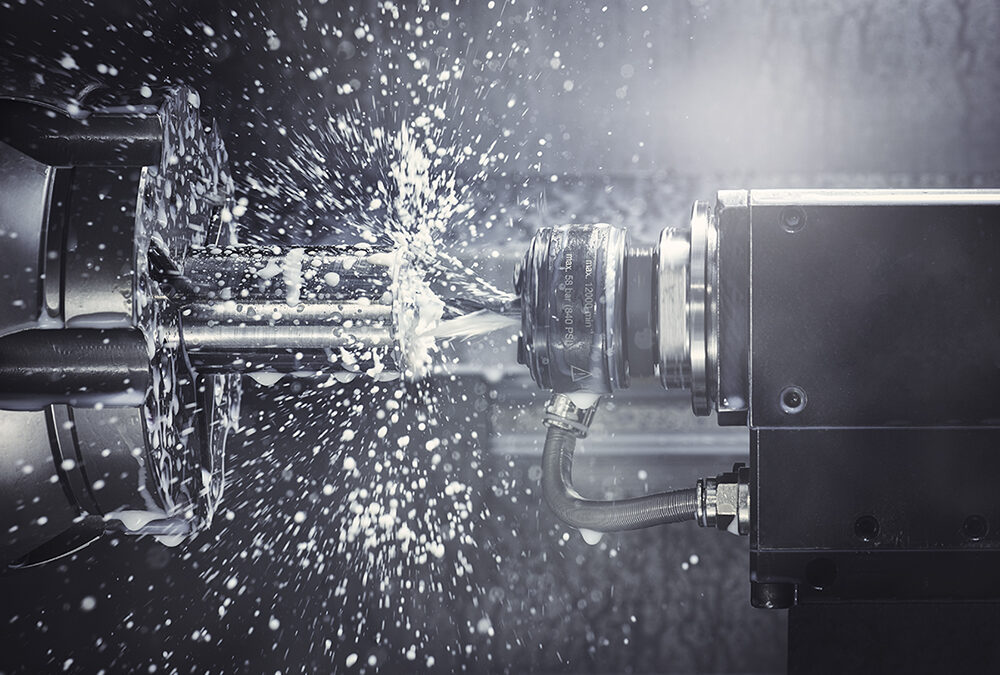

Many manufacturers still consider drilling a very forgiving process that requires less precision on the part of toolholding. Realistically though, nothing could be further from the truth. Toolholding is the key to boosting drilling accuracy, which in turn, can improve...

by REGO-FIX Team | Apr 29, 2022 | Blog

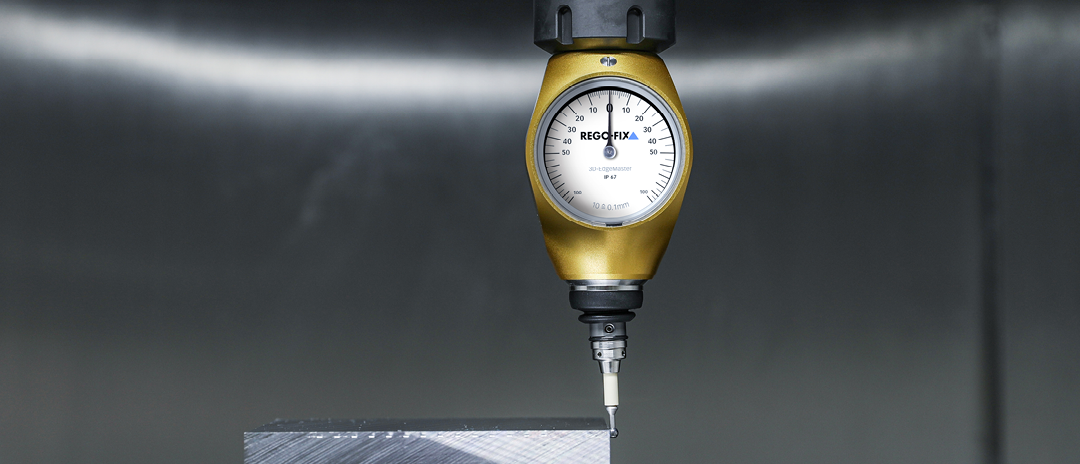

Long before the pandemic upset the global labor environment, REGO-FIX was working on limiting human intervention in the production processes. There are some things you cannot automate, but you don’t need human interaction to swap a work piece from one machine to...

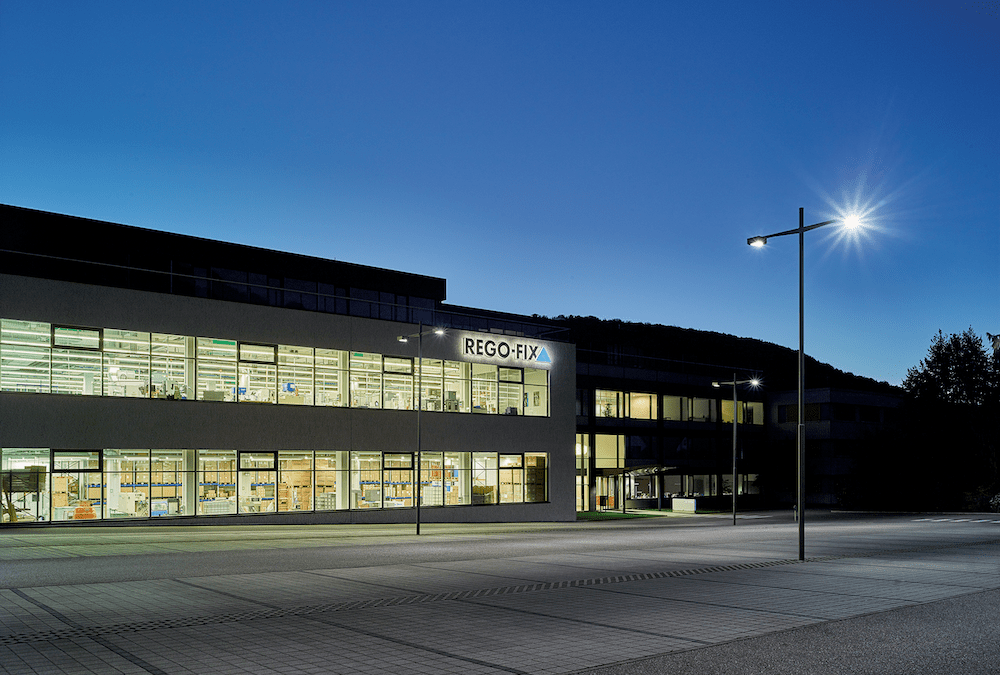

by REGO-FIX Team | Apr 14, 2022 | Blog

REGO-FIX couldn’t maintain its superb customer relationships without two essentials: the right toolholding to get the job done and the inventory availability to ensure that customers receive what they need when they need it. Large orders or small, we’re...

by David | Mar 31, 2022 | Blog

The essence of reliability is predictable, indisputable performance. In toolholding, that means never having to worry about product performance because you can depend on what you buy to deliver what you need. Quality is reputation, and REGO-FIX never stops striving to...

by REGO-FIX Team | Mar 17, 2022 | Blog

I believe that companies that have adapted best to the pandemic are also the ones who witnessed positive effects, and that REGO-FIX is among them. A main reason that REGO-FIX adapted quickly to COVID is that the Swiss government allowed companies to decide for...