MOLD AND DIE

Complex workpieces, ongoing cost pressure, diverse materials. From micro machining with tiny stepovers and minuscule tools to larger projects with an equal need for precision, mold and die work demands predictable accuracy and repeatable precision. Your customers expect complex forms with quick turnarounds, which leaves you no time for finicky tooling. Even the smallest irregularity or departure from dimensional specifications can land your work on the scrap pile, and every second of cycle time counts against your deadline.

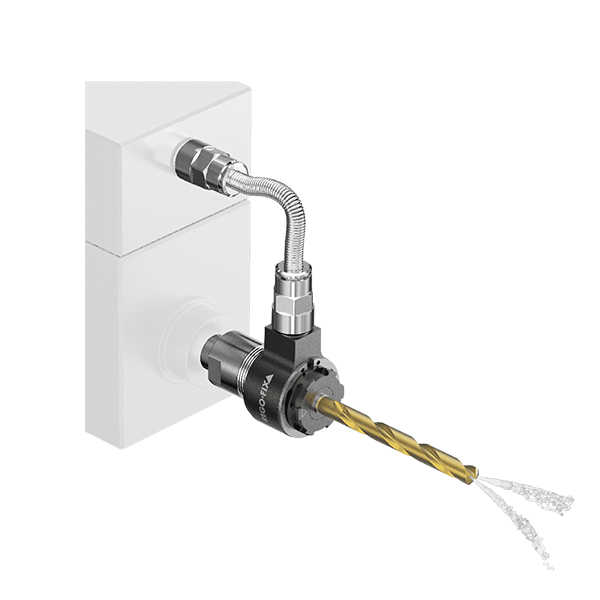

Vibration and runout head your list of forces to combat. You choose your tools carefully, selecting the finest options for long life and high reliability. Your toolholder selection deserves the same performance and care.

REGO-FIX supplies the industry’s widest variety of collet and toolholder types, lengths and diameters, all with unfailing repeatability, vibration damping and lasting quality. That lineup includes small-diameter and high-speed holders and systems for cutting tools down to 0.0079″ (0.2 mm) in diameter. Our full selection of clamping and torquing devices, along with a wide variety of other accessories, assures you of the flexibility you need to meet any customer requirement.