COMPOSITES

Time-intensive production, expensive tools, thermal challenges. From aerospace and defense to automotive, wind energy and sporting goods, many industries now rely on composite parts that combine strength with light weight to provide increased performance. As you know all too well, the same attributes that make these materials desirable also make them tough to machine.

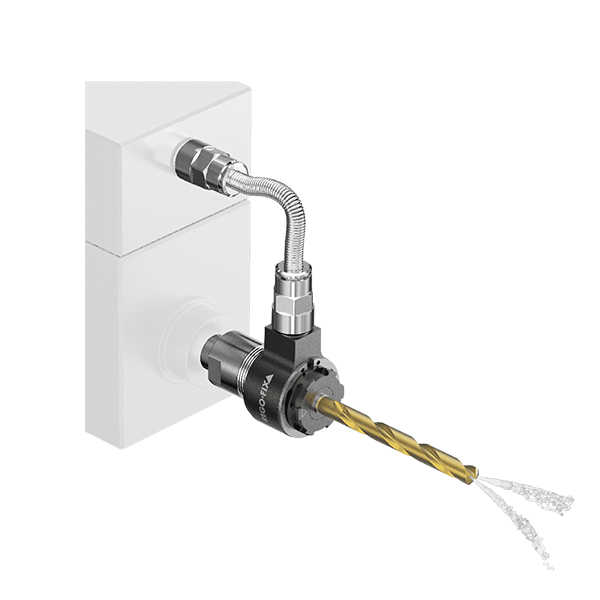

With composites, your dry machining process produces heat every time you begin one of the many passes required for these complex parts. Heat shortens tool and toolholder life, raises vibration and runout, and reduces the clamping force of many toolholder systems. None of these factors improve manufacturing results – and the wrong toolholder system can exaggerate, if not cause, every one of them, with expensive cutting tools and the need for high-speed reliability on the line.

REGO-FIX supplies the industry’s widest variety of collet and toolholder types, lengths and diameters, all with unfailing repeatability, vibration damping and lasting quality. Our full selection of clamping and torquing devices, along with a wide variety of other accessories, assures you of the flexibility you need to meet any customer requirement.

Toolholding Recommendations

powRgrip

In less than 10 seconds, this innovative solution clamps tools as small as 0.008″ (0.200 mm) with system runout of less than 0.0001″ (3µm) – all with no heat or fumes.