by David | Mar 7, 2022 | Blog

Our customers always want to take advantage of the full capabilities of their machine tools. They never want to use anything in a machine that can hamper its performance. That’s why the two keys to proper toolholding – and machining results – are correct setup...

by REGO-FIX Team | Feb 18, 2022 | Blog

Smaller components and tighter tolerances drive today’s need for speed and precision, as tools get smaller, machines get faster and high-performance cutting is now the norm. Instead of making slow, deep passes across a part, today’s machines use light cuts...

by REGO-FIX Team | Feb 8, 2022 | News

WHITESTOWN, Ind., February 7, 2022 – With the utmost technical support in mind, REGO-FIX has added Mark Ohlfest to the company’s OEM Technical Support team aimed at strengthening ongoing relationships with original equipment manufacturers (OEMs). Ohlfest...

by REGO-FIX Team | Feb 4, 2022 | Blog

All REGO-FIX customers depend on us to deliver the consistent high-quality toolholding that helps make their machining processes a success. Our industry partners – machine tool builders and cutting tool manufacturers – rely on our products as well, but we offer these...

by REGO-FIX Team | Jan 21, 2022 | Blog

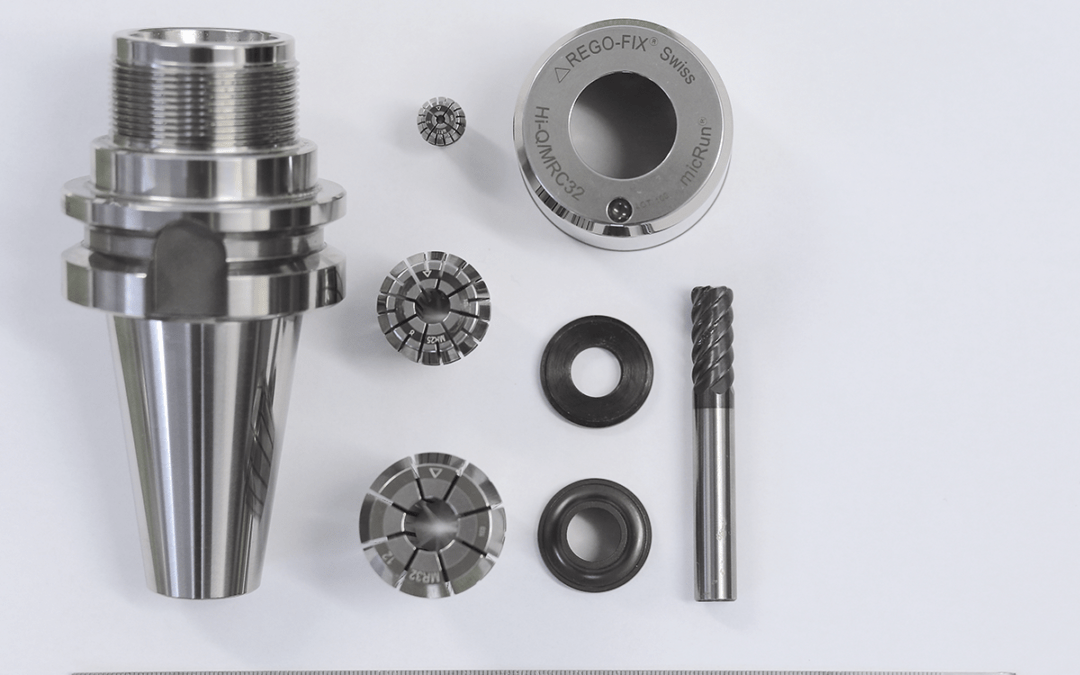

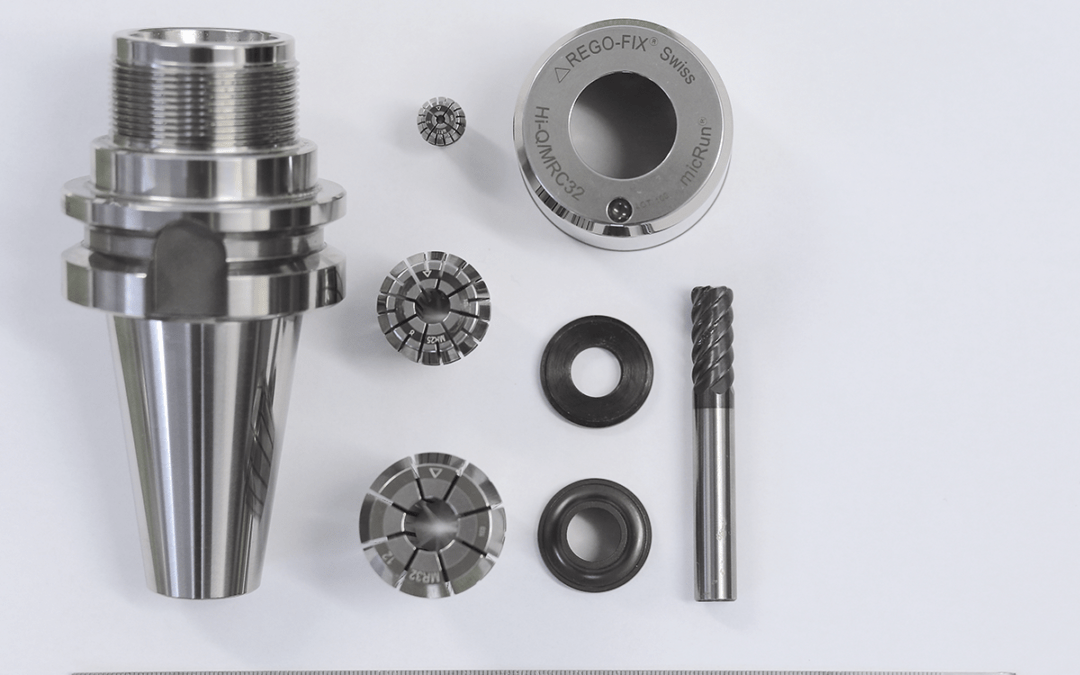

The predictable precision of REGO-FIX powRgrip® gives you the vibration damping, low runout and secure toolholding to complete challenging machining tasks with high accuracy and confidence. The ease and convenience of the powRgrip system begins with the speed of its...

by REGO-FIX Team | Jan 14, 2022 | News

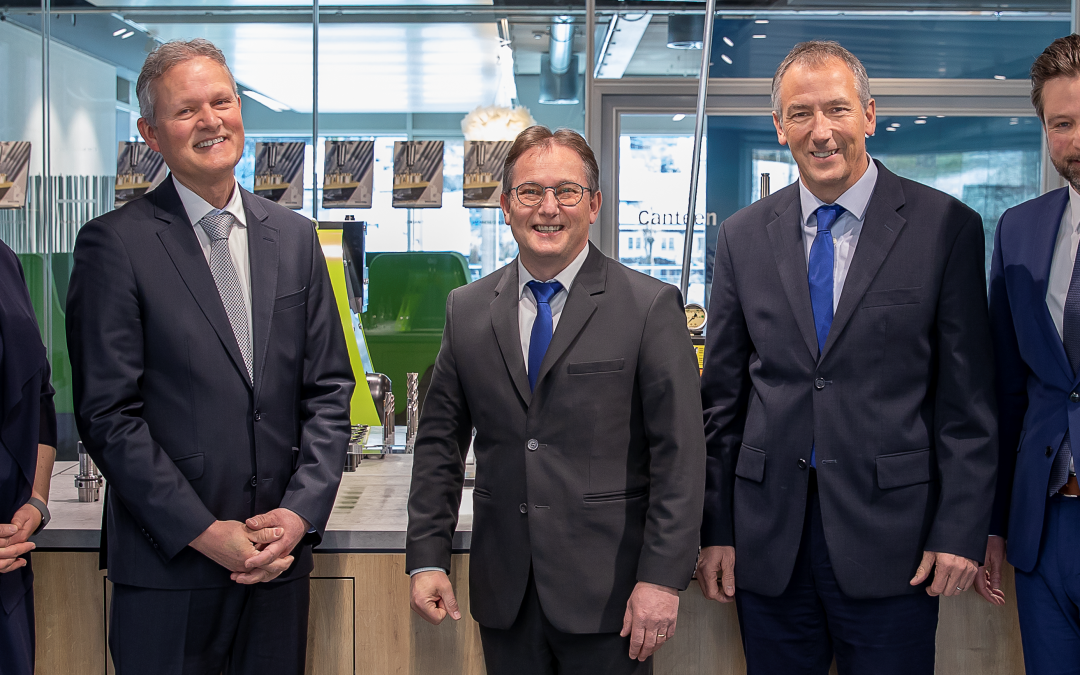

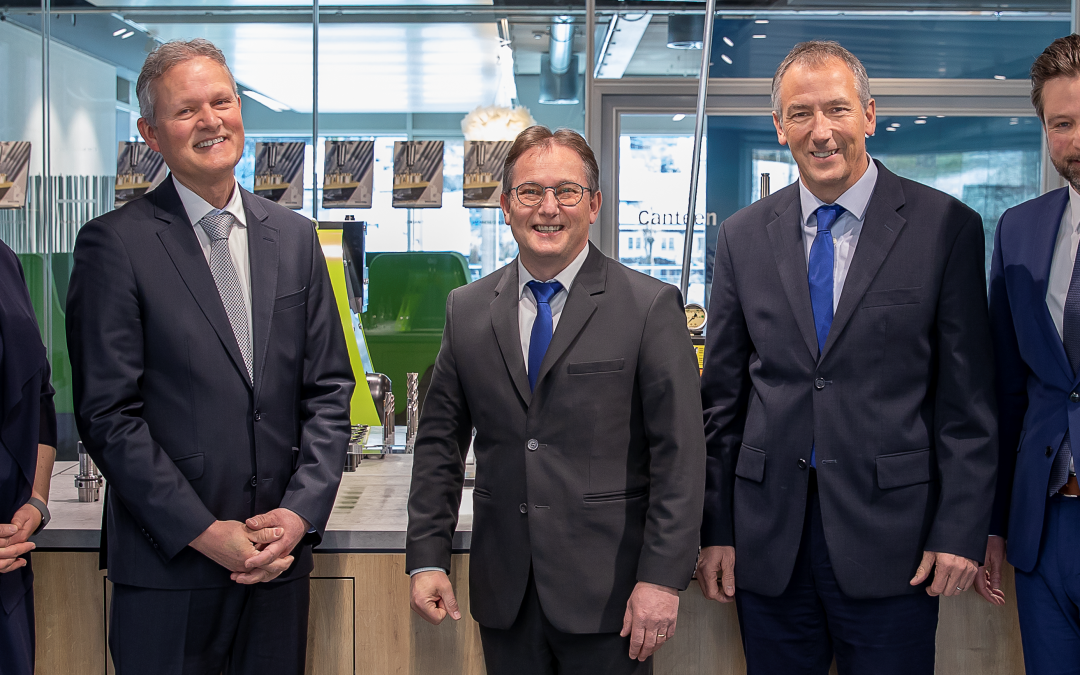

REGO-FIX AG has signed an agreement to acquire the majority equity interests of the Swiss based company GEWITEC AG. GEWITEC is an established, global provider of standardized precision parts for the tool and machine industry and for OEM solutions. “Working with...

by REGO-FIX Team | Jan 7, 2022 | Blog

Does your shop treat drilling like a primary process or an afterthought? You may think that if you’re planning to ream or bore holes to their finished diameter, then maybe it doesn’t matter if you take some shortcuts, use an old toolholder and don’t...

by REGO-FIX Team | Dec 17, 2021 | Blog

Composites add new challenges to manufacturing, especially in the process of machining. Unlike metal workpieces that behave like normal solids, composites consist of layered materials bound together with adhesives. That makes them porous, which in turn makes them...

by REGO-FIX Team | Dec 3, 2021 | Blog

Just down the road from REGO-FIX’s U.S. headquarters in Whitestown, Indiana, Indianapolis-based machine tool builder HURCO has become a valued partner with whom we share a mutually beneficial relationship. At HURCO, REGO-FIX toolholding solutions – typically...

by REGO-FIX Team | Nov 19, 2021 | Blog

Longevity and quality go hand in hand when it comes to the machine tools on your production line, and respect for your tools pays big dividends. A machine tool can give you more than a decade of service, if you choose a well-made piece of equipment and take good care...